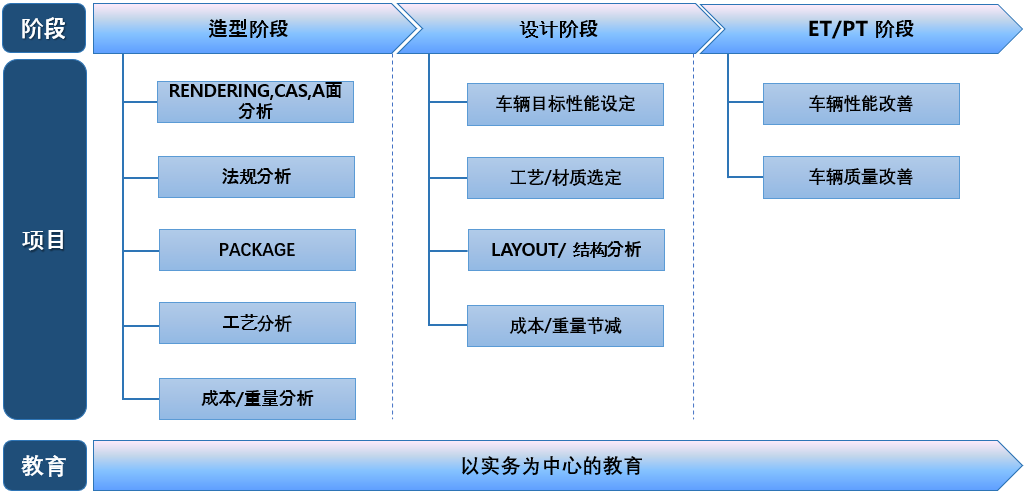

ADENG (AD Engineering) works from the initial vehicle development stage to mass

production.

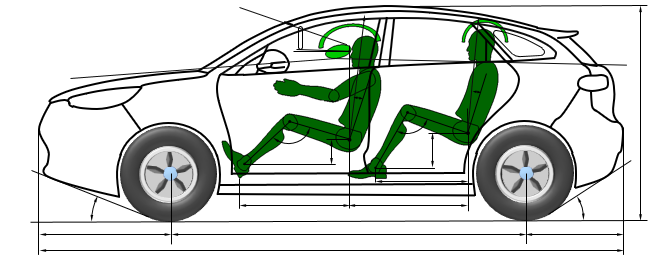

1. VEHICLE PACKAGE SECTOR 。

- We work from basic package to detailed package according to the vehicle development concept.

2. STRUCTURAL DESIGN SECTOR .

- Under/Upper body, Exterior, Interior structural design of vehicle.

1) Rendering, Clay model, CAS, A Class analysis and improvement of problems.

2) Creation of structural design proposals and structural plans.

3) Create a Typical section.

Reflects basic structure, mounting structure, gap and face difference prevention structure,

emotional quality improvement structure, structure based on construction methods and

materials,structure considering assembly tolerance, structure to prevent Vehicle recurrence

prevention structure, etc.

4) Application of new technology of materials and methods.

Analyze other companies' vehicles and apply new technologies of materials and construction

methods considering future sales timing.

5) Weight/Cost Reduction.

In order to achieve the target cost/weight, the product method/material and structure are

analyzed and reflected in the design plan and structural design from the beginning.

6) Layout and part structure detailed design.

Reflected in structural design considering material, construction method, mounting method

and location, gap/surface difference prevention structure, emotional quality, noise prevention,

weight/cost, etc.

7) Improve product quality.

Improvement of product deformation, raw materials, formability, appearance quality, etc.

8) Improvement of problems in parts tests and vehicle tests.

Improvement of problems such as appearance, deformation, and NVH that occur after testing.

9) ET/PT vehicle quality improvement.

ET/PT vehicle quality problem analysis and improvement.

- We carry out design standardization work to prevent structural design problems and quality

recurrence problems that cause deterioration in vehicle quality and increase in development

cost/part cost.

|